Prerequisites

The wear scar and the surrounding area have been measured. In this particular case, the hip head has been measured on an OrthoLux 4 AB with 901,800 data points.

Step 1: Identify the wear patch.

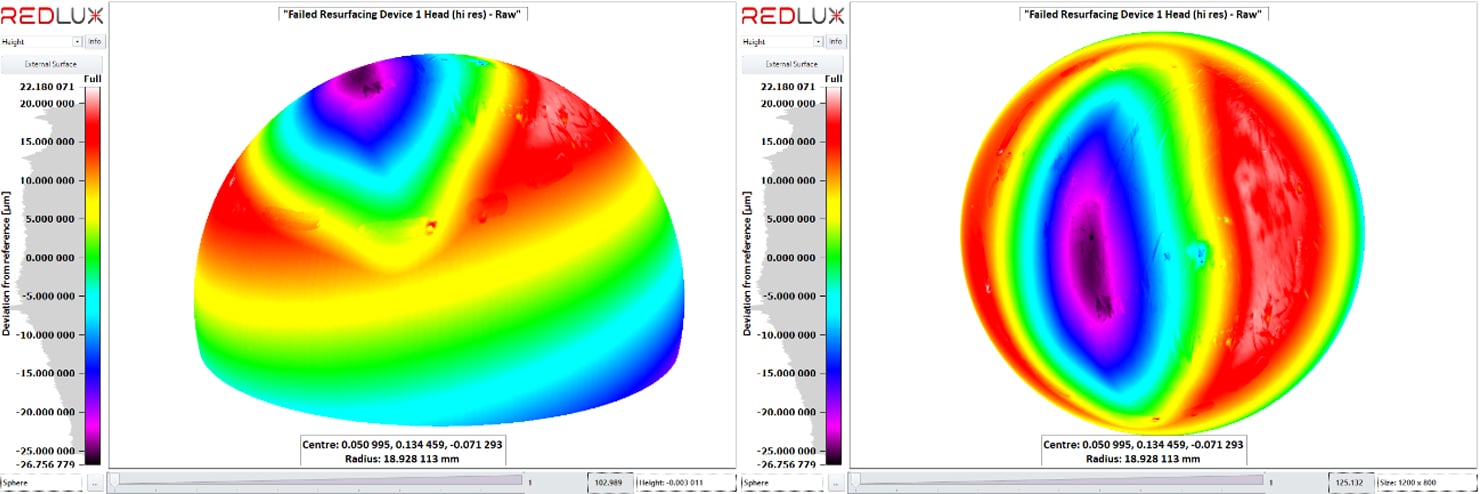

This is usually achieved by fitting the nominal shape to the surface. Initially this includes all data points:

Raw data set after initial sphere fit

Raw data set after initial sphere fit

From this initial fit, it is possible to separate the original surface, which is later used as the datum for wear measurements from the wear scar.

Step 2: Exclude the wear scar.

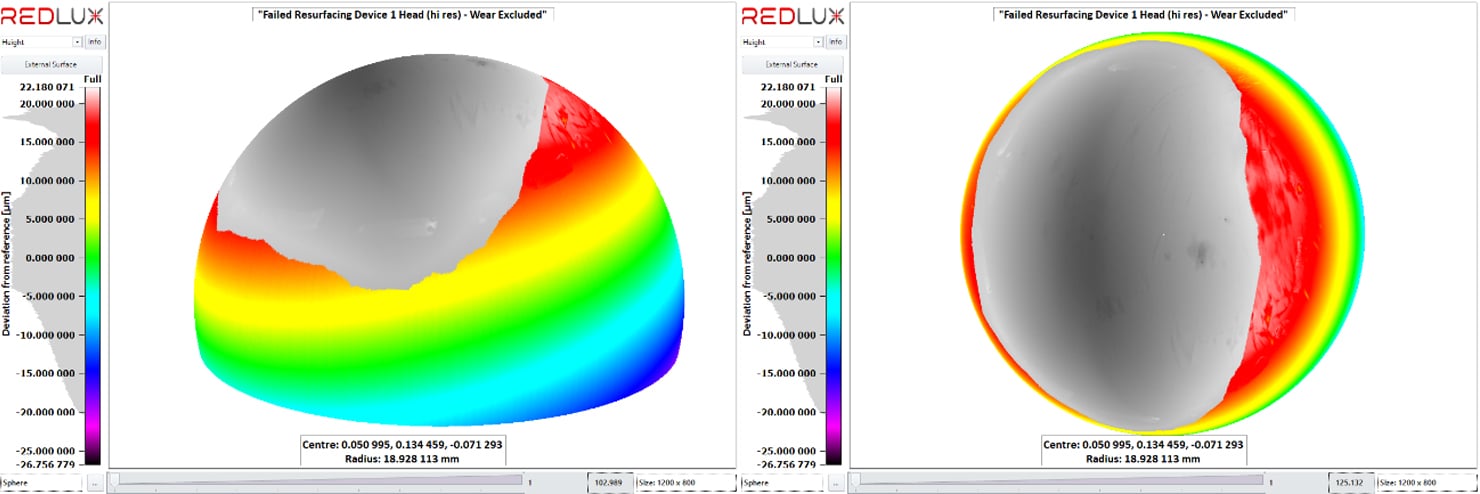

The next step is to exclude measurement points on the wear scar and material accumulation around the wear scar. This important step allows establishing a clear datum surface for further calculations.

Wear scar excluded

Wear scar excluded

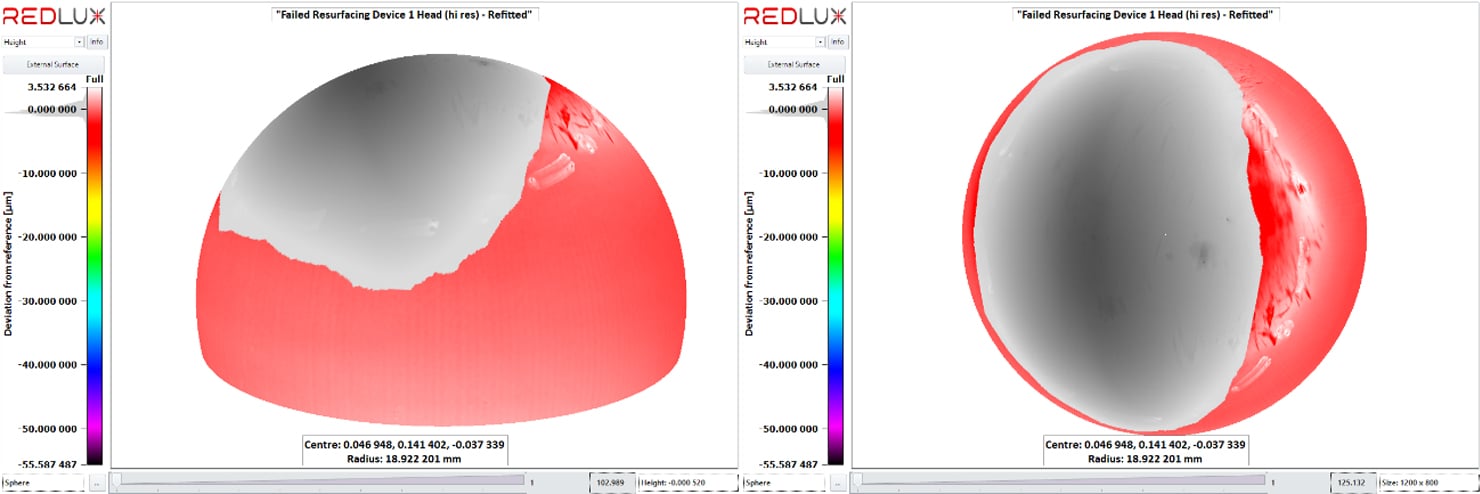

Step 3: Refit to datum surface.

Now that the original, unworn surface has been established as a datum, the sphere fit can be repeated.

Sphere fit to datum surface

Sphere fit to datum surface

Steps 2 and 3 might have to be iterated a few times until all of the wear scar and material accumulation have been isolated and removed (note the white region of deposited debris which has been highlighted with a marker pen to the right of the wear scar).

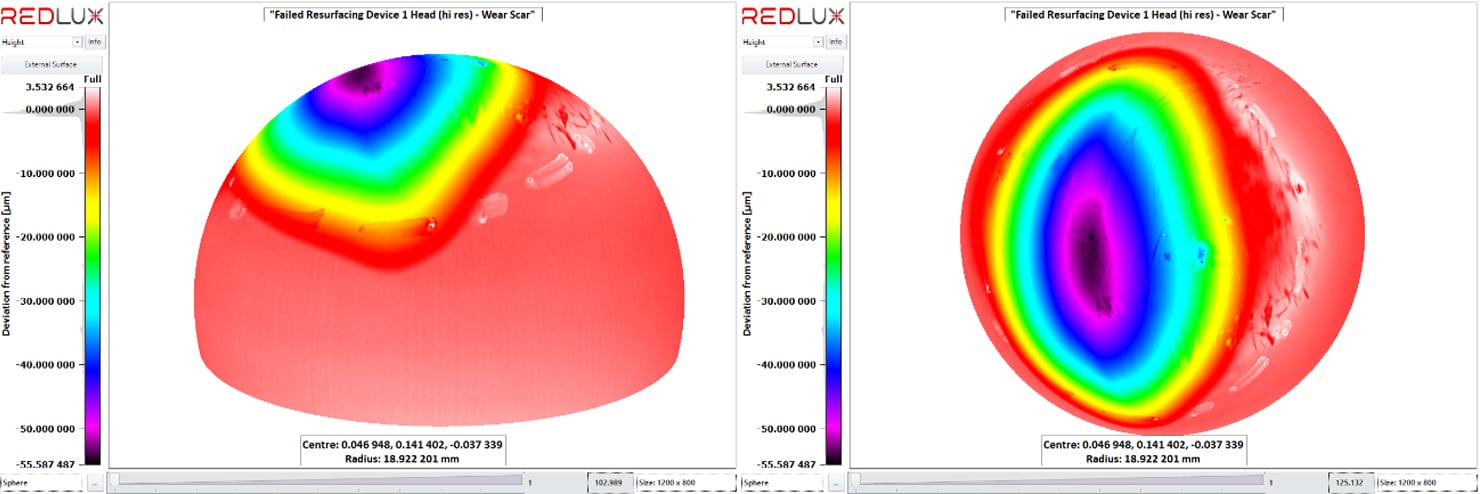

Step 4: Include all data points and characterise wear.

Sphere fit to datum surface

Sphere fit to datum surface

In this case, the wear scar is 53.7 µm deep and the wear volume is 18.6 mm³.